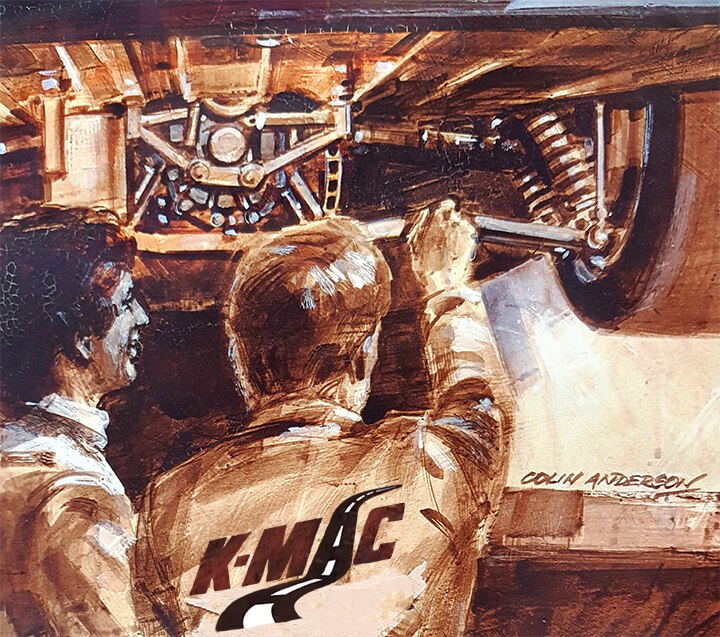

About Us

“STRUT TOPS”, “WISHBONE” AND “BUSHING KIT” MANUFACTURERS!

WITH PROUDLY “IN-HOUSE” MANUFACTURE (NOT JUST SOURCING IMPORTS / RELABELLING). ALLOWING TOTAL CONTROL OVER QUALITY ● ● ● AND RAPID / CONSTANT PRODUCT DESIGN / DEVELOPMENT !

Results speak for themselves ● ● ● situations where Race Safety scrutineers –

Testing and evaluating rule (for strength and reliability) –

That only KMAC adjuster Kits are allowed to be used.

● ( EVEN THE MOST EXOTIC MAKES BMW ‘M’ , Mercedes AMG / Black )

BECAUSE OF COST SAVINGS AND THE EVER INCREASING SPEED OF OEM ASSEMBLY LINES

THE OFTEN QUOTED / RE ASSURING “FULL FRONT & REAR ‘4’ WHEEL ALIGNMENT “ IS ONLY “TOE” IN / “TOE” OUT (DIRECTIONAL) ADJUSTMENT.

COSTLY, PREMATURE EDGE TIRE WEAR BY EXCESS ADJUSTMENT ONLY ALTERS

WEAR POSITION AND ACTUALLY INCREASES OVERALL WEAR RATE

ALONG WITH THE UNIQUE KMAC INNOVATIVE PATENTED DESIGNS THAT HAVE SET NEW STANDARDS FOR – STRENGTH, QUIETNESS, EASE / RANGE OF ADJUSTMENT

(and we do appreciate any constructive ideas on how we can further improve our market leadership.)

MAJOR DESIGN BREAKTHROUGHS :

McPherson Strut Suspensions

REPLACES THE EXISTING STRUT TOP MOUNTS (NO MODIFICATIONS). REINFORCING THE STRUT TOWERS AND WITH THE UNIQUE KMAC PATENTED DESIGN PROVIDING THE BIGGEST (AND QUICKEST) ADJUSTMENT RANGE OF BOTH CAMBER AND CASTER. STREET/RACE SETTINGS CAN BE RECORDED AND CHANGED IN 30 SECONDS – JUST THE TIME TAKEN TO LOOSEN THE 3 TOP MOUNT NUTS. ANOTHER KMAC PATENTED DESIGN FEATURE ALLOWS THIS FAST ADJUSTMENT TO BE MADE ACCURATELY UNDER LOAD.

THE CAMBER & CASTER ADJUSTABLE TOPS ARE AVAILABLE IN 3 STAGES:

● STAGE 1 – (STREET) – Steel with captive ball race thrust bearings (similar to OEM) and performance elastomer centers.

● STAGE 2 – (STREET / RACE) – KMAC “All The Features Not Found In Other Brands” …. Not steel or soft billet alloy, but the very highest aircraft 7075 grade aluminum with “extra H/duty” self align spherical bearings (self lubed – PTFE lined). These are then encased in elastomer to dampen / extend life for day to day commuter use. Separate extra H/Duty fully sealed radial thrust bearings are also incorporated – massive 85mm (3 3/8”) diameter specifically designed to take steering loads and prevent annoying spring noise through dragging/binding (plus KMAC centers are also “replaceable” for virtual lifetime usage ). Kits are designed for minimum stack height and include OEM / Factory diameter top coil seats in alloy. Plus separate seats to take all brands of coil overs 60 to 70 mm I.D.

● STAGE 3 – (FULL RACE) – Similar to stage 2 but no Elastomer / Flex for tauter / quicker steering response times! – More effective shock control. Specifically for full race applications where ride harshness and durability are not the criteria.

THE UNIQUE KMAC PATENTED DESIGN ADJUSTMENT SYSTEM FOR ABOVE KITS PROVIDES the “quickest/biggest” range (plus increased strength / support) supersedes the current industry standard which has been around for years – a non-flexible ‘slot’ design with spherical bearings.

This slot design, besides having less adjustment because of the need for access to the hold down bolts, is also time-consuming to adjust and on many vehicles requires removal of the strut.

NOTE : Most brands the “single” spherical ball is also taking the steering loads.

Unlike KMAC where separate, purposely designed vertical thrust bearings are also incorporated (fully sealed – massive 85 mm diameter )

Reducing steering effort and preventing annoying noise through spring drag / binding.

Newer Strut Type Suspensions

WHERE THE UPPER MOUNT HAS NO MOUNTING STUDS.

Brought about by the OEM industry simplifying manufacturing techniques. KMAC’s design challenge here was to design, develop a system whereby substantial adjustment could be made to change both Camber and Caster settings simply and accurately yet (because of the limited accessibility) without the need for any structural modifications.

Design for popular – 2 Bolt Flange Struts (Chapman) Suspensions – KMAC MAXI CAMB (TM)

CAMBER KITS CURRENTLY ON THE MARKET FOR THESE TYPE STRUTS ARE CALLED “CRANK BOLTS” – WHICH IS AN OFFSET BOLT DESIGN. BASICALLY ONE OF THE 2 CRITICAL BOLTS THAT HOLD THE STUB AXLE / WHEELS ON IS DOWNSIZED!

For example a 14mm bolt is replaced by a 12mm crank shape bolt – this 2mm reduction is then used to gain adjustment.

This undersized / weakened crank bolt design was rejected by KMAC as these 2 bolts are a critical suspension component, (holding the stub axle / wheels on) and the new car industry isn’t noted for oversizing componentry!.

INSTEAD THE KMAC PATENTED DESIGN ● ● ●

● Eliminates / Supersedes the need for downsize crank bolts.

● Provides 2 times the adjustment range.

● Unlike crank bolts – features a fail safe / non slip lock system always maintaining and ending the frustration of Camber setting / changing!

Just 3 KMAC MAXI CAMB Part No’s cover over 400 makes and models of this popular Front and Rear Suspension “2 Bolt Flange” Strut System.

A Design was required for Strut Type Suspension where there is no coil spring/strut tower clearance.

Example: Honda / Acura, Civic, CRV, Element, Integra, Odyssey (‘Strut’ front suspensions). Like earlier models, they have no Camber or Caster adjustment ex-factory.

Where there is no adequate clearance outer diameter of coil spring to inside of strut tower for Camber and Caster travel / adjustment. KMAC again invented, patented and manufacture unique ‘Top of Strut’ kits, to provide separate Camber and Caster adjustment with original OEM coil diameter. There are also kits available for adjustable coil overs.

A Design for Ball Joint Suspensions

KMAC REVOLUTIONIZED THE ADJUSTMENT OF THIS TYPE OF (DOUBLE WISHBONE) SUSPENSION BY INVENTING AND PATENTING A UNIQUE SLOT SYSTEM, WHEREBY AN ACTUAL BALL JOINT COULD BE ADJUSTED IN OR OUT TO VARY CAMBER SETTINGS (BY UP TO 3 OR 4 °).

THIS KMAC DESIGN HAS NOW BECOME THE WORLDWIDE INDUSTRY STANDARD FOR WISHBONE SUSPENSION ALIGNMENT ADJUSTMENT.

LIKE ALL KMAC KITS, THEY ARE BOLT-ON AND NO SPECIAL TOOLS ARE REQUIRED.

KMAC’s challenge here was to design an Eccentric Bushing Adjuster

It is often said “ The Simplest Design Is The Best Design”. Once you get your head around this KMAC design break-through, you realize ● ● ● IT IS JUST THAT !

A SIMPLE METHOD WAS REQUIRED FOR THE NUMEROUS PIVOTED BUSH CONNECTION POINTS FOUND THROUGHOUT VEHICLE SUSPENSION SYSTEMS, SO THAT FRONT CAMBER AND CASTER OR REAR CAMBER AND TOE COULD BE ADJUSTED EASILY TO OVERCOME THE CURRENT INACCURATE AND LABOR INTENSIVE ADJUSTER DESIGNS OVER THE LAST 40 YEARS, WHERE IT IS NECESSARY FOR TIME CONSUMING REMOVAL OF THE BUSHINGS EACH TIME FOR A SETTING CHANGE THEN THE INACCURATE TRIAL AND ERROR REPOSITIONING AT A NEW OFFSET POSITION.

THIS NEW KMAC INVENTION NOT ONLY ELIMINATING THIS TIME CONSUMING NEED FOR DISASSEMBLY AND GUESS WORK RE NEW SETTINGS – INSTEAD NOW PRECISE “SINGLE WRENCH” ADJUSTMENT ACCURATELY ON CAR (UNDER LOAD – DIRECT ON ALIGNMENT RACK).

KMAC THEREFORE HERE AGAIN SET NEW INDUSTRY STANDARDS with this design breakthrough inventing and patenting a system whereby the original size hexagon bolt head could be easily and simply rotated on vehicle to precisely adjust each bush to the required alignment setting, then locked in this position.

TO COMPLIMENT AND COMPLETE THIS “NEW BUSH ADJUSTMENT METHOD”

WE DETERMINED IT WAS TIME THAT A 100% FAIL SAFE “LOCKING SYSTEM” WAS ALSO CREATED…. SECURITY OF LOCKING ESPECIALLY IMPORTANT WHEN IT COMES TO WORKING PARTS IN VEHICLE SUSPENSIONS.

For too long majority of industry locking methods in use today world wide rely on lock nuts with reverse teeth (or similar design spring washers). But they are totally dependant on friction/ full tightness everytime or inevitably failure occurs.

To resolve “once and for all” the KMAC design lock system does not rely on friction. Once in place the ultimate result – the security of knowing a KMAC lock nut cannot inadvertently loosen – no matter what tension is applied.

NOTE: All above KMAC “eccentric adjuster bush kits” are also supplied with extraction / insertion tools where required to further simplify installation and are available for Audi, BMW, Mercedes etc. Virtually every make from Audi to Volvo.

MONOBALL / 2 AXIS – SELF ALIGN BUSHINGS.

MOST “AFTER MARKET BUSHINGS” are promoted as H / Duty and “improve brake and steering response” by replacing the OEM oil filled and air voided rubber bushings with urethane.

BUT WITH TODAYS “MULTI LINK” CONTROL ARMS (with different mount angles), it is essential in these situations to retain mono ball / 2 axis movement so that arms can still travel through there required suspension arcs without binding, locking up – causing undue ride harshness and can lead to even more / not less wheel hop, loss of traction and to arm breakage !

We saw the need for two designs allowing to importantly retain the security, peace of mind of OEM design – But the security of high strength forget alloy arms. Not the reliance on replacing with welded, fabricated steel arms.

● BMW AND MERCEDES – front Camber and Caster. Rear Camber (and extra Toe) to suit all models (1968 to 2021) – Camber essential to allow to change “Tire Contact Angles” resolving costly, premature edge tire wear, improving traction. Caster to re-establish settings after Camber change, correctly resolving steering pull, improving brake and steering response.

● POPULAR MUSTANG – Background is that Ford starting in 2005 redesigned the Mustang front strut towers resulting in “aftermarket” Camber and Caster kits once installed required the time consuming removal each time a ‘setting’ needed to be changed. Or the structural modification to each strut tower to gain access.

● KMAC CHANGED ALL THAT – inventing/patenting and displaying at SEMA trade show 2006 a unique system whereby a adjustable Camber and Caster strut mount could be adjusted from engine bay without modifications needed or strut removal. The actual design also providing the biggest (and quickest) adjustment range.

2005-2014 STAGE 2 (STREET/RACE) P/N 182816-2L, STAGE 3 (FULL RACE) P/N 182816-3L

2015-2021 STAGE 2 (STREET/RACE) P/N 182916-2L, STAGE 3 (FULL RACE) P/N 182916-3L

MUSTANG REAR-SIMILAR DESIGN BREAKTHROUGH – models 2015 to 2021. Again K-MAC setting new standards – surpassing all other brands in the 2 important areas of Camber adjustment: “ FAST / TIME SAVING INSTALLATION” and “EASE OF ADJUSTMENT”.

THE PATENTED DESIGN providing for the 1st. time “easily accessible” rear adjustment – precise (single wrench) accurately under load direct on alignment rack.

DOUBLING THE EXISTING ADJUSTMENT RANGE to cater for conditions encountered in day to day commuting – high cambered roads, altered height through lowering or load carrying, fitting wide profile tires / wheels and/or curb knock damage.

TRACK DAYS – being able to adjust for maximum traction. P/N 182926 G

● SAME WITH THE 2011 ONWARDS CAMARO – also a total OEM “front strut tower” redesign eliminating 40 years of prior “mount bolts” for retaining the top strut mounts. Necessitating now the drilling of strut towers to mount “aftermarket” Camber and Caster kits then difficult access to change settings.

FOR CAMARO AGAIN THESE MODELS KMAC SHOWED THE WAY FORWARD – INVENTING AND DISPLAYING AT SEMA 2012 THE TECHNIQUE WHERE A PRECISELY ADJUSTABLE STRUT TOP ( WITH EASY ACCESS TO ADJUST BOTH CAMBER AND CASTER) COULD BE FITTED – “BOLT- ON , WITH NO DRILLING NECESSARY”.

AVAILABLE IN (2011-2015) STAGE 2 (STREET/RACE) P/N 202116-2L

(2015-2021) STAGE 2 (STREET/RACE) P/N 202216-2L

STAGE 3 (FULL RACE) P/N 202216-3L

● DEALERS – YOUR CUSTOMERS EXPECT YOU TO SELL # 1